How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

Bale ties allow us to condense, palletize and easily move a wide variety of recyclable products and waste materials including plastics, paper, aluminum, and cardboard. Compacting using either a horizontal or vertical baler is always followed by the use of some type of securement often times this comes in the form of a bale tie. Bale ties are most commonly used in vertical balers and sometimes used in horizontal balers. Properly sizing your baler for the correct bale tie will likely save you time and or money down the line. Here are some tips to help you navigate your way through sizing:

Measure your bale

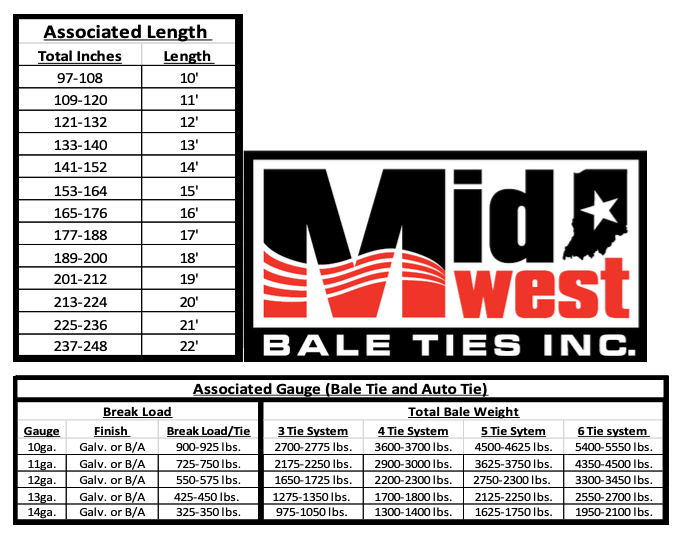

The first and most important thing to do when trying to get to the correct size of bale tie is measuring your bale. Grab a tape measure and get the full dimensions of an already completed bale. If you are working with a vertical baler you will need measurements on height and width and if you are working with a horizontal baler you will need measurements for width and length. These measurements will directly impact the length of your bale tie.

Weigh your bale

You have your measurements, now its time to get your bale to a scale and see how much your made bale weighs. This weight doesn’t need to be exact but you should be able to get somewhere within 10 lbs. of an accurate weight. You might also consider weighing multiple bales and averaging the group. It’s common for bales to vary in weight depending on who makes the bale and who is feeding the baler. The weight of the bale will help diagnose the gauge or thickness of wire that will best fit your needs. The most common gauges requested are 12 gauge and 13 gauge however 11 gauge and 14 gauge are also available.

Understand what is being baled

Now that you have your measurements and your weight it’s time to understand and think critically about the composition of the straight you are processing. A material like paper doesn’t really have much expansion once the baler releases the bale, however a straight like plastic will expand. This is important to understand because this may affect the type of finish (black annealed or galvanized) bale tie will best fit your application.

Count your wires

This one is simple, how many wires do you use to make a bale with your particular type of baler? This number, like the weight of your bale, also helps us calculate what gauge bale tie will be most effective for your system.

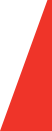

So, we have a bale measured and weighed, we know we are baling paper so not too much expansion after release and we know we are using 5 wires per bale in the vertical baler we are using, what now? Now we just use the formula of (height”+width”)x2+12”. So, for example, we will use the height of 48” and a width of 38” for a total of 86”. Now we have 86” times 2 gives us 172” plus 12” comes to 184”. Using the chart below we know we need a 17’ bale tie.

Now we have our length its time to calculate our gauge and finish. Our bale weighs 2200 lbs. and we know we are using 5 wires per bale. So using the other chart below we can see that 13ga wire has a break load strength of 425-450 lbs. we take that 425 and multiply by 5 and we get 2,125-2,250 lbs. of total break strength. We also know we are baling paper so not too much expansion after release so we can go with a standard galvanized finish.

Looking For Bale Ties in the Midwest?

Feel free to use the materials and examples below to do your own sizing assessment, shaving off a couple of feet or going to a lighter gauge could save you up to 10% on cost and the correct length could help cut time off on tying off the bale. Also, keep in mind we do samples bundles of 20-25 wires if you would like to try a different length or gauge bale tie than the one you are currently using. If you have any questions or would like to request a sample bundle please don’t hesitate to email sales@midwestbaleties.com or call 765-364-0113.

Asking and answering the questions above and communicating that information to your supplier should allow them to accurately and efficiently give you the best and most cost-effective length and gauge product. We offer free samples on bale ties and baler wire to customers who are looking to get hands-on experience with a different gauge or length of tie and encourage anyone to reach out with questions or requests. In addition, we offer a sizing chart to better understand if you are getting the correct material for your current system.

Galvanized vs. Black Annealed: What’s the Difference?

Galvanized vs. Black Annealed: What’s the Difference?

In the world of bale ties, there are three common finishes or types of wire used in the manufacturing process. Wire with one of these three finishes will ultimately be used to manufacture your bale tie. Each type has unique traits and properties that give the bale tie an individual look and feel.

Listed from most common to least common would be Galvanized, Black Annealed, and Painted/Coated. Below is a description of each finish as well as some attributes and features.

Galvanized Wire

The most common type of wire finish used in the production of a bale tie is galvanized. Galvanization is the process of coating or bathing a raw steel or “bright basic” wire in a pool of molten zinc. This often occurs as a close to the drawing process or directly after the wire has been drawn to the desired thickness or gauge.

How do you Make Galvanized Wire?

The process of galvanization allows the bale tie to be used in wet and humid conditions without compromising its structural integrity. In short, galvanized bale ties can be used and should be used when storing your baled material in a location that has exposure to the elements.

Galvanized bale ties will appear to be silver or metallic with very little oil or residue allowing for clean usage. Galvanized wire tends to be stiffer with less elongation than a black annealed bale tie. Galvanized wire is the most durable and versatile of the three types of finishes, particularly when storing bales in an outdoor area.

Black Annealed Wire

The second most common type of wire finish when talking about bale ties is black annealed. The annealing process takes a simple post drawn “bright basic” steel wire and heats it in an oven or kiln changing the chemical composition. This process softens the wire as well as changing its color from more of a rough grey or silver to more black or brown color.

What is Black Annealing?

Black annealed bale ties will appear black or dark in color and feel slightly oily. Using a black annealed bale tie, you will also find that the wire has between 5-10% more elongation making it more ideal for baling materials that expand after releasing RAM pressure on the baler.

Unlike galvanized bale ties black annealed bale ties will rust if used and stored outdoors often causing the wire to fail. 50- and 100-pound Baler wire is almost always made with black annealed wire because of its versatility and rate of elongation.

Painted or Coated Wire

The final type of wire used to manufacture bale ties is the coated or painted wire. A painted wire is typically a bright basic wire coated with a colored coating or “paint” that has dried giving the wire a rough textured feel.

What is Coated Wire?

A painted wire bale tie will perform similar to a galvanized bale tie and is designed to be acceptable for bales stored outdoors. Though often clean during handling and tying sometimes issues will occur in either the manufacturing process or during shipping or usage causing the paint to chip and the wire underneath to become exposed, this exposed wire will often fail when exposed to the elements. Painted bale ties are the least common type of bale tie and are often replaced by the more affordable black annealed or the more durable galvanized bale tie.

What is Baling Wire Made Of?

Each of the finishes above has unique features and benefits. Depending on your particular system, the material you are processing, and your budget one of these 3 finishes are correct for you bale tie. In addition, make sure you take into consideration where the bales are stored once they are made this might limit your options.

If you are still unsure about which finish is the best for your application feel free to reach out to us at info@midwestbaleties.com and we can assist you with getting the correct size, gauge and finish bale tie for your needs. Also available are sample bundles which are smaller bundles of 25-30 wires designed for testing a specific length and gauge, typically these bundles are shipped UPS freight at no charge to the customer.

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

Bale ties and baling wire are consumable products that enter your facility, get used by the team that handles your baling, and then leave your facility surrounding some type of waste or recyclable material. Bale ties and baler wire are a very small part of what you and your company do on a day to day basis. However, if your bale ties or baler wire begins to fail or the size and gauge of the wire being used is not ample and accurate a small problem grows into a much larger issue. Waste and recyclable material begins to pile up, manpower is spent cleaning up after broken bales of material, and timelines and production schedules are affected.

The following questions are designed to help you and your team understand more about the product/products you are using to bale your materials and help you better purchase from your supplier. Asking these questions before you make a bale ties or baler wire purchase should help you communicate your specific needs to your supplier as well as potentially save you and your company money by purchasing the most cost-effective product for your needs.

What are we baling?

The list of materials our bale ties and baler wire are used to hold together is ever-changing. Some of the more common materials we see bailed are paper, cardboard, plastic, textiles, and aluminum. Each type of material has different properties and reacts differently when the pressure of the baler is released. For example, bales of plastic bottles tend to have significantly more expansion than bales of paper products which tend to hold there form better. This difference in material and response could potentially mean a black annealed wire or bale tie would be more suited to your specific application. Not only would this simple change potentially enhance the effectiveness of the system it would also reduce costs because black annealed material is less expensive than galvanized material.

Where are our bales being stored and for how long?

Once your material has been compacted and your bale tie or baler wire has secured your bale where does that bale go for storage? Does your team transport it to a covered trailer? How long do they sit until being picked up? Do your bales get transferred to a pallet and set it outside until the next pickup to save on space? Do your bales simply get moved to a designated spot in your warehouse? Black annealed material, which is more cost, can have issues when not stored in a covered or sheltered area away from the elements. Galvanized material can be stored in most spaces without potentially compromising the integrity of the wire. Whatever your system or method of storage its important to consider how your wire is affected.

How much do your bales weigh?

The weight of your bale is very important when diagnosing the correct gauge of wire needed to hold the load securely. Common problems that occur when the material being used is not ample for the weight of the bale being processed are delaminated heads and breakage of wire. We advise taking 3-5 bales of each material your facility regularly bales and weighing them to get an average weight/bale. Given this weight and the number of ties being used we should be able to get you the most cost-effective gauge wire which many times reduces the weight per bundle, in turn, dropping your cost per bundle.

What are the dimensions of your bales?

The length, height and width of your finished bale speaks directly to the length of the bale tie needed to effectively secure your material. Bale dimensions are generally specific to the type and size of baler your team uses. Lengths typically vary between 10 and 22 feet and a rule of thumb would be to always go slightly longer than what you think you need and as you find what works scale back 6” to 1’ at a time until you find the exact length that works for you and your team.

Asking and answering the questions above and communicating that information to your supplier should allow them to accurately and efficiently give you the best and most cost-effective length and gauge product. We offer free samples on bale ties and baler wire to customers who are looking to get hands-on experience with a different gauge or length of tie and encourage anyone to reach out with questions or requests. In addition, we offer a sizing chart to better understand if you are getting the correct material for your current system.

How to Save Money on Bale Ties: Sizing, Quantity, and Freight

How to Save Money on Bale Ties: Sizing, Quantity, and Freight

“How can I save money on my bale ties and baler wire?” is a question that often arises when speaking with our customers and partners in market, especially given all the rising costs associated with baling and reselling your material. There are several ways to cut costs on the bale ties and/or wire you are currently consuming. In the following paragraphs, we are going to discuss 3 ways you and your company could potentially cut costs on bale ties and baler wire.

Sizing

Many times the size of the bale tie currently being used is not the most effective option. The bale tie currently being used by your team is likely ample in size to consistently handle the weight of the bale you are processing and also likely ample length that your operators have plenty of slack to tie off the bale. These are all good outcomes, however, if you are trying to cut some costs and get the most optimal and cost-effective solution more could be done.

Cutting a foot off the length of the bale tie you are currently using would reduce the weight of the bundle, in turn, dropping the cost of the bale tie. Switching from a 14’ x 13ga bale tie to a 14’ x 13.5ga bale tie reduces the weight of the bundle thereby dropping the cost. Moving from a galvanized finish bale tie to a black annealed bale tie reduces cost because the raw material is less expensive. We make this process easy by always providing customers with free samples so they can test out what makes the most sense given the system they have in place. In addition, we also provide a simple sizing sheet to better help get to the best solution for your business.

Quantity

For many of our customers that bring in bale ties and baler wire the quantity they order is the same over and over. 10 bundles of 14’x14ga. galvanized single loop bale ties every 2 months or one full pallet of 11ga baler wire every 6 months. Looking at the quantity and, beyond that, looking at what space is available to potentially allocate towards a larger quantity is a simple way to reduce the delivered cost per bundle. Though it can be difficult finding a balance between storage space allocation and bale ties consumption is something every company should consider.

Going from purchasing 20 bundles of 21’x12ga galvanized single loop bale ties to purchasing 40 bundles of 21’x12ga galvanized single looped bale ties would save somewhere between $2.00 and $3.00 per bundle. Delivered cost moving from 20 bundles of 21’x12ga galvanized single looped bale ties to 80 bundles of the same material, which would constitute a bulk material price would reduce your cost per bundle by between $4.00 and $6.00 per bundle. Space is a concern in any warehouse situation but if you have some space available it may be worth taking on a larger stocking position to reduce costs. Please contact us and ask about max gaylord pricing and bulk discount if it something you think could work for your facility.

Freight

Freight is a necessary evil when factoring in delivered cost. The rates are always changing and seasonal rates cause prices to roller coaster. While we have some dependable carriers and fair LTL rates in place for most states, reducing freight cost is an easy way to drop the delivered price for bale ties, baler wire, and even stem wire. As you consider the above ways to reduce costs please also consider how the product is being shipped and who is shipping. Oftentimes better rates are available through carriers you are presently working with. In addition, we can also solicit quotes from carriers outside our main network and potentially arrange a better shipping cost to reduce your delivered price. These carriers sometimes have extended schedules but as long as you are not in immediate need are a good solution.

When dealing with larger orders that surpass 4 pallets we also can reach out to some of our bulk carriers for quotes based on the total weight of the load which oftentimes tremendously reduces the delivered cost of your bale ties and/or baler wire. Working with freight can be frustrating and time-consuming but once a system is in place it should be very simple for your purchasing agent to simply duplicate your last order and the same cost will be in place.

Hopefully, the information above is valuable and you are able to take advantage of some of the ways available to save on the cost of your bale ties, baler wire, and stump wire. We are always available to discuss and troubleshoot any issues or potential ways we can get you what you need in the most cost-effective manner. Please reach out if you would like to take advantage of a free sample bundle of product or get an updated quote with different quantities.

Why are Bale Ties and Baling Wire Essential?

Why are Bale Ties and Baling Wire Essential?

As a good majority of people in the work force are either working from home, or even worse, being laid off because of precautions put in place to fight Covid-19 I am forced to ask myself “why am I still hard at work?” What about a bale tie or baler wire is so essential that we need it maintain a sense of life as we know it and fight the hardships caused by the ongoing quarantine. Bale ties, baler wire, or any other wire used to hold together compacted waste created by our society and economic routine is much more important than we realize.

First, let us cover the basics. Waste materials at any scale are typically either disposed of in a trash can and sent to the local landfill or Incinerator or they are sent to a facility to get sorted and grouped together to then be resold. When waste goes to the landfill or incinerator that waste has finished its lifecycle and will either be burnt for energy or be covered by more waste and dirt to break down organically. However, if waste is sent to a sorting facility and compacted together into bales it can be resold for a profit. This is where the bale tie or wire tie comes into play. Bale ties and/or wire ties are used to secure the bales safely and neatly so they can be sold and transported to another company which will result in that material being reused. In a nut shell bale ties and baling wire allows for recycling to take place in a clean and efficient manner.

Now that we have that covered lets ask the question why is recycling so essential right now given everything that is going on? For one, I think we would agree that recycling is always important. The more waste we are able to reprocess and reuse the better for the environment, the healthier the environment the more we can enjoy it. Right now though during the spread of this virus recycled materials are used to make some of the most sought after products used and consumed. Bale ties and baller wire are often at the start and the end of that loop.

An example of this loop would be plastic bottles. Plastic bottles are discarded as waste in the recycling bin. That bin is collected and sent to a processing center to get sorted and aggregated into similar types or grades of plastic. Once enough material of the same grade of plastic is collected the material is put into a baler. The baler compacts the material, in this case plastic bottles, into a large cubed mass called a bale. While compacted this bale is secured with either a bale tie or some type of baling wire where it can be neatly stacked and stored until enough material is processed to fill a truck. Once the processing facility has a trailer full of material they are able to sell these baled plastic bottles to either a plastics processing facility or a manufacturer that is able to in turn use the raw plastic material to produce another type of plastic bottle and fill it with hand sanitizer. Once used the bottle from the sanitizer is processed as waste and the cycle begins all over again.

This process is true of many of the products that are cleared off the shelves in times of social distress and worry. Some other products the bale tie and baler wire help get to your store shelves are: toilet paper, paper towel, bottled water, cleaners and sanitizers, various types of boxes and packaging, and even plastic gloves and masks. The truth is thousands of people working in hundreds of different industries and sectors ARE essential and contribute to manufacturing a product like a bale tie or improving a process that truly is necessary to the economy and sustaining life as we know it. Midwest Bale Ties salutes all those working through these tough times as well as those quarantined in their homes. Together we can and will get through these trying times.

Value: What Does Your Baler Wire, Bale Ties, and Hi-Tensile Wire Supplier Do to Help Your Business?

Value: What Does Your Baler Wire, Bale Ties, and Hi-Tensile Wire Supplier Do to Help Your Business?

Some synonyms we use for the word “value” are importance, worth, and usefulness. Thinking about the role we play in our customers’ business and how we can continue to provide value, we acknowledge that we take on certain responsibilities. Although bale ties and baler wire may be a small aspect of your business, you should still expect a certain degree of value from your supplier. The attributes and responsibilities listed below are what we believe makes a good wire supplier.

Monitor and Ensure Quality

All wire is not created equal. Wire is sourced from many different countries and continents. The quality of any bale ties and/or baling products you purchase starts at the mill where the raw material (steel) comes from and how it is treated throughout the forming process. As a supplier and manufacturer, it’s our responsibility to consistently monitor the quality coming from the source mill, as well as evaluate if that material is meeting the needs of our customers. Sometimes wire can be too dry, too stiff, or too oily for a customer’s needs. Making adjustments to supply and making adjustments to a customer’s specific needs are a key “value” your bale ties, baler wire, and carrier wire supplier should be providing.

Education

As a wire supplier and manufacturer of bale ties and baler wire, what we do is not rocket science. It is our business to know the wire and know which wire is best suited for a specific purpose. Taking our knowledge and passing that along to your customers is definitely one of the key values we bring to their business. Sometimes customers are using bale ties that are too long, and sometimes customers are using wire that’s too small in diameter. Understanding these problems, working through them with the customer, and providing solutions that are the most cost effective for the customer is a fundamental way your supplier can and should show their importance or value to your business.

Dependability and Timeliness

More times than not, we receive orders that come attached to aggressive and speedy timelines. Hearing the customer ask, “How fast can you get this out?” or “Can you ship this today?” is a daily occurrence. As a supplier and manufacturer, it’s our job to make adjustments and do our best to get the customer what they need in a timely fashion. Not being able to adjust and cater to those needs typically results in slower operational speed for the customer, as well as material piling up at the baling site causing both a safety hazard and a lot of additional work to keep the material sorted and contained. The dependability and timeliness of your supplier getting you the bale ties, baler wire, and carrier wire you need and their ability to adjust and cater to short timelines is a huge “value” they can bring to your business.

Packaging and Flexibility

Typically, bale ties come in either 250 pieces per bundle, 125 pieces per bundle, or 62 pieces per bundle. Lengthwise, customers typically order by the foot rounded to the next highest foot. As a supplier and manufacturer, we have the ability to adjust bundle sizes, lengths (including half-lengths), and the type of packaging used for the product we ship. Part of our role as a supplier includes asking the right questions and catering to the needs of our customers, such as adjusting and advising them on ways they could be saving money on material or adjusting their packaging to best suit their needs. Your current supplier should be in tune to what you need from your baler wire, bale ties, and carrier wire and be willing to make the necessary adjustments based on those needs.

Hopefully, your current supplier takes your needs seriously and is able to translate those needs into more value to your business and baling operation. Bale ties, baler wire, and stump wire are only a small part of the chain used to process and bale your recyclable materials, but if handled correctly, it should be one that causes very little stress. If your current supplier isn’t checking all the boxes above, maybe it’s time to find a supplier more in line with your needs and goals. A “valued” supplier often goes unnoticed but can bring a great deal of worth to your business and overall operations.

At Midwest Bale Ties, we pride ourselves on being a valued supplier and understanding the importance of quality bale ties and baler wire. Our staff is highly educated and dedicated to providing the utmost care and support for all of your baling wire and ties needs. Contact us today to see how we can help add value to your business!

What’s in Your Baler?

What’s in Your Baler?

People commonly ask, “So what do you do for a living?” I often explain that I work for a company called Midwest Bale Ties where we manufacture bale ties and baler wire. The response to that, 9 times out of 10 is, “Bale ties, huh? Like the stuff farmers use to bale hay?!” It turns out that hay or straw only makes up around 1%-2% of the material our products are used for. In fact, bale ties and baler wire are used to hold together a plethora of different materials. Each material – or straight – has its own characteristics and depending on those characteristics a different type of wire is best suited to keep the bale secure. Below we are going to briefly discuss different materials that are commonly baled and what types of wire are best suited to secure those bales.

Paper

Out of all the materials recycled in the US, paper makes up a larger percentage than plastic, glass, and aluminum combined. Falling within the paper classification, you have several types: OCC (old corrugated cardboard), mixed paper, old newspapers, high-grade de-inked paper, and pulp substitutes. From a composition standpoint, these materials, once compressed in a baler, do not have a lot of expansion and are able to form dense, well-compacted bales that have good memory. Because of these features, you should be able to use a standard galvanized or black annealed bale tie or baling wire to secure and store.

Plastic

One of the fastest growing recycled materials, plastic is broken down into 5 subheadings: HDPE (milk jugs, oil bottles, toys), PET (soda bottles, water bottles, medicine containers), LDPE (shrink wrap, plastic wrap, garment bags), PP (bottle tops, carpet, refrigerator containers), and PS (disposable utensils, meat packaging, protective packaging). Plastics are known to have good memory, so determining the correct wire or bale tie needed can be more difficult than other straights. Typically, plastic bales will use a larger gauge or thickness of wire or bale tie in order to combat the expansion of the material once the bale is released. It’s also not unheard of for bales of plastic to be secured with a hi-tensile wire, which is a unique type of steel designed to have a much higher break strength. Knowing your straight, bale dimensions, and bale weight is key in understanding what type of wire is needed to secure your bale.

Non-ferrous metals

Non-ferrous metals include aluminum, copper, lead, and nickel; essentially any metals that do no contain iron. Some common materials that fall under this classification would be aluminum cans and copper plumbing pipes. For the most part, metals tend to compact well and hold their form so standard bales ties and wires should be acceptable when securing a bale of non-ferrous metals.

Textiles

Believe it or not, clothing is frequently baled. Sometimes the bales of clothes are shipped to a different county to be reused, and sometimes the clothing is baled and later broken down to reuse the fibers to make other products. Nonetheless, textiles and clothing are common straights that use bale ties and/or baler wire to secure. From a memory perspective, textiles do not pose much of an issue. Typically, you are able to use standard galvanized bale ties or baler wire when securing bales of textiles.

Foam

A material we don’t often think about being baled and recycled is foam. Used for mattresses, seats, and many other products, foam has unbelievable memory. Because of this, the wire needed to secure the bundle must be stronger than your typical galvanized bale tie. Typically, foam is baled and secured using a hi-tensile, bright basic double-loop bale tie. Double-loop bale ties must be fitted to the exact specifications of your bale size, so it’s very important to measure your bale before placing an order.

Tires

Tires are everywhere, and they are a terrible material to send to a landfill because they take an extended time to break down. Because of this, they are typically baled and recycled using large industrial shredders. Bales made of tires are typically very dense and have a great deal of memory. A lot like foam, bales of this material are often secured using double-loop bale ties, though there have been instances when we have found our customers can also use single-loop bale ties to secure these bales. Again, knowing your bale dimensions and weight is helpful when communicating to your supplier what product you might need.

E-Waste

E-waste breaks down several ways and typically goes through an involved process which extrudes some of the more valuable elements of the material. From a characteristic standpoint, bales of e-waste would fall under plastics more than anything else. Single-loop bale ties or standard baler wire can be used because the material has lower memory.

Hay

This is the granddaddy of all bales. Hay has been baled since the beginning of the industrial revolution. The machines used to bale hay typically use a 14.5-gauge wire commonly referred to as “farmer wire” or “6500”, which is the amount of feet in a 100# coil of that material.

After digesting the information above, you should be a little more versed in the world of baling and which wire is associated with which type of baling. The types of materials being baled vary greatly, and it’s our hope that when you speak with someone about a bale tie and or baling wire you have a much broader understanding of this topic. As you can see, there is much more to a bale tie than just something used to bale hay. If you ever have any questions about your baling operation or would like to explore alternative wire options, please reach out to us with your bale dimensions, bale weight, and the material you are baling and we would be glad to discuss the most efficient, cost-effective way to fulfill your needs.

Why American-Made Bale Ties Are Your Best Bet for Quality and Safety

Why American-Made Bale Ties Are Your Best Bet for Quality and Safety

When it comes to choosing bale ties for your packaging and bundling needs, the market is filled with a plethora of options. However, the question of quality and safety is paramount, especially when dealing with materials like steel. In recent years, the superiority of American-made bale ties over overseas alternatives has become increasingly apparent.

The Quality of American-Made Steel:

One of the primary factors contributing to the higher quality of American-made bale ties is the quality of the steel used in their production. The United States is known for producing high-quality steel, adhering to strict industry standards and regulations. This results in a stronger, more durable product that is less likely to fail or cause safety concerns.

In contrast, overseas steel production, particularly in countries with lax regulations and oversight, may not meet the same rigorous standards. The use of low-quality steel in the production of bale ties can lead to a multitude of problems, such as corrosion, brittleness, and susceptibility to breaking under pressure.

Safety Hazards of Poor Quality Bale Ties:

The use of inferior bale ties made from low-quality steel can pose significant safety risks to employees and others involved in the handling, transport, and storage of baled materials. Some potential safety hazards include:

Breakage:

Bale ties made from low-quality steel may snap under pressure, causing bales to become unstable or fall apart. This can lead to accidents, injuries, or even fatalities if workers are in the vicinity.

Sharp edges:

Poorly made bale ties can have sharp edges, posing a risk of cuts or puncture wounds to workers handling them. In severe cases, these injuries could lead to infections or other complications.

Corrosion:

Low-quality steel is more susceptible to rust and corrosion, which can weaken the bale ties over time. This increases the likelihood of breakage and potential accidents.

Inconsistent sizing:

Inferior bale ties may not be manufactured to consistent dimensions, making them difficult to use and less effective in securing bales. This can lead to unstable bales, increasing the risk of accidents during handling and transport.

The Importance of Choosing American-Made Bale Ties:

Selecting American-made bale ties is not only an investment in quality and durability but also a commitment to the safety and well-being of your employees and others who may come into contact with your baled materials. By choosing domestically produced bale ties, you can have confidence in the quality of the steel used and the manufacturing processes, ensuring that your bales are securely bound and free from potential hazards.

The superior quality of American-made steel and the adherence to strict industry standards make American-made bale ties a safer and more reliable option than their overseas counterparts. Investing in high-quality bale ties can help prevent accidents and ensure the safety of your employees and others involved in the handling, transport, and storage of baled materials. Remember, when it comes to bale ties, quality and safety go hand in hand.

To guarantee the best quality and safety for your baling needs, consider reaching out to Midwest Bale Ties, a manufacturer of 100% American steel bale ties, for a trustworthy and dependable solution.

The Top 5 Common Uses of Baling Wire

The Top 5 Common Uses of Baling Wire

Baling wire, also known as farm wire or soft wire, is a versatile and durable material that has been used for a variety of purposes for many years. It is a type of wire that is made of low-carbon steel and is commonly used to secure and bundle materials. Here are the top five common uses of baling wire in recycling and industrial spaces:

Recycling:

Baling wire is essential in recycling facilities to compact and bundle various types of recyclable materials such as cardboard, paper, plastics, and metals. These materials are typically bulky and take up a lot of space, but baling wire helps to compress them into compact bales, making them easier to store, transport, and sell.

Construction:

Baling wire is widely used in the construction industry to secure and hold building materials in place. This wire is commonly used to tie rebar together, hold concrete forms in place, and secure scaffolding. Baling wire is also used in demolition projects to pull down walls and other structures. Additionally, baling wire is used for hanging acoustical ceiling grid systems, securing ductwork, and holding insulation in place.

Agriculture:

Baling wire has long been a staple of agriculture, primarily for securing hay bales. It is also used to tie up loose fence wires and to secure gates. In addition, baling wire is used to hold together bundles of crops during harvesting and transport.

Packaging:

Baling wire is sometimes used as a packing material for shipping heavy items. It can be wrapped around boxes or crates to hold them together and prevent them from shifting during transportation. Baling wire is strong enough to withstand the weight and pressure of heavy items.

Manufacturing:

Baling wire is often used in the manufacturing industry to secure and hold various types of products and components in place. It is commonly used to bundle wires and cables, secure pipes and tubes, and hold together large pieces of machinery. Additionally, baling wire is commonly used for hanging parts for powder coating, dipping items into a galvanization tank, and various finishings.

In conclusion, baling wire is a versatile and indispensable material in recycling and industrial spaces, as well as in the construction and manufacturing industries. Its strength and flexibility make it an ideal material for a wide range of applications, from compressing recyclable materials to securing building materials, hanging acoustical ceiling grid systems, securing ductwork, holding insulation in place, and finishing products in the manufacturing process. As such, baling wire will continue to play a critical role in these industries for many years to come.

To learn more about how Midwest Bale Ties can help you with your wire needs, call our experienced team at 765-364-0113.

Why Would my Business Benefit from Baling Waste Materials?

Why Would my Business Benefit from Baling Waste Materials?

Baling versus throwing materials in the trash might seem like a trivial choice, but it can have a significant impact on the environment, the economy, and even your bottom line. In this blog post, we will explore the benefits of baling and how it can help us reduce waste at your facility and protect our planet.

What is Baling?

Baling is the process of compacting waste materials into tight bundles, called bales, using specialized machines called balers. These machines are designed to compress and bind different types of materials, such as cardboard, plastic, metal, textiles and paper, into a compact form that is easier to handle, transport, and recycle.

Benefits of Baling

Reduces Waste Volume and Disposal Costs

Baling waste materials significantly reduces the volume of waste, which translates into lower disposal costs for businesses and organizations. By compacting waste into bales, you can fit more waste into a single container, reducing the frequency of pick-ups and lowering the transportation costs associated with waste disposal.

Increases Recycling Rates and Revenue

Baling also makes it easier to recycle waste materials by separating them into different categories and preventing contamination. For instance, baled cardboard is easier to handle and transport to recycling facilities, where it can be turned into new paper products. Similarly, baled plastics can be melted down and used to create new plastic products, reducing the need for virgin plastic production.

By increasing recycling rates, businesses can also generate additional revenue by selling their baled materials to recycling companies. This can help offset the costs of baling and waste disposal and contribute to a more sustainable business model.

Improves Workplace Safety and Cleanliness

Baling waste materials can also improve workplace safety and cleanliness by reducing the risk of accidents and spills. When waste is left unbaled, it can take up valuable space, creating hazards and clutter that can be dangerous for employees. By compacting waste into bales, businesses can free up space and reduce the risk of tripping, falling, or other accidents.

Protects the Environment

Finally, baling waste materials can have a positive impact on the environment by reducing the amount of waste that ends up in landfills. Landfills are not only expensive to operate, but they also contribute to greenhouse gas emissions and pose a risk to human health and the environment. By recycling and reducing waste, we can conserve natural resources, reduce pollution, and protect the planet for future generations.

Conclusion

Baling waste materials is a simple but effective way to reduce waste, save money, and protect the environment. By compacting waste into bales, businesses can increase recycling rates, generate revenue, improve workplace safety and cleanliness, and contribute to a more sustainable future. If you’re interested in starting to bale materials or if your company is already baling and needs assistance with your wire choices, reach out to our experienced team at 765-364-0113. Midwest Bale Ties is here to help. Let’s chat!