Why Quality Matters: The True Cost of Cheap Baling Wire

Why Quality Matters: The True Cost of Cheap Baling Wire

In the competitive market of baling wire, the allure of lower prices can be tempting. However, the initial savings from purchasing cheaply made, imported baling wire can quickly evaporate when considering the broader implications on productivity, maintenance costs, and overall efficiency. This article explores why investing in higher-quality, domestically produced baling wire not only sustains the health of your equipment but also proves more economical in the long run.

The Hidden Costs of Low-Quality Baling Wire:

- Increased Machine Wear and Tear: Cheap baling wire often fails to meet the stringent quality standards required for high-performance baling operations. This inferior quality can lead to frequent wire breaks and jams, which not only slow down operations but also place undue stress on baling equipment. Over time, this increased wear and tear can lead to costly repairs and even more significant downtime.

- Efficiency Losses: Efficiency in baling operations is paramount. Low-quality wire may not tie bales as tightly and consistently as higher-grade wire, leading to less secure bales that can come apart during handling or transport. This inefficiency can result in double handling of materials, increased labor costs, and potential losses from damaged goods or materials.

- Increased Downtime: Every minute a baler is down for wire-related issues translates directly to lost productivity. High-quality domestic wires are manufactured to strict specifications that ensure reliability and reduce the likelihood of machine downtime. On the other hand, the inconsistency of cheaper wire can mean more frequent stoppages to address breaks, tangles, or jams.

- Customer Service and Support Issues: Dealing with suppliers of cheap baling wire often means compromised customer service. The lack of prompt, reliable support can exacerbate downtime and may lead to prolonged disruptions in your operations. Domestic suppliers typically offer more responsive and accessible customer service, helping you resolve issues quickly and efficiently.

- Long-Term Financial Implications: While the upfront cost of cheaper, imported baling wire might appear lower, the long-term financial burden it imposes often outweighs these initial savings. Investing in higher-quality wire minimizes the risk of unforeseen expenses related to equipment damage, operational inefficiencies, and poor bale integrity.

Choosing the right baling wire is a decision that impacts not just the cost of supplies but the entire operational workflow. Quality should be the paramount concern when selecting baling wire, as the true cost of using substandard materials can far exceed the price paid at purchase. By opting for superior, domestically produced baling wire, businesses can achieve greater reliability, efficiency, and ultimately, profitability.

For those in the baling industry, the message is clear: investing in quality is not just a choice but a necessity for sustainable operation. Choose wisely, and ensure your operations are built on a foundation of quality that supports long-term success.

If you’re ready to explore high-quality, domestically produced baling wire solutions that promise reliability and superior customer service, contact the Midwest Bale Ties sales team at 765.364.0113 today or request a quote here. Let us help you find the perfect baling wire for your needs and ensure your operations run smoothly and efficiently.

Spring into Efficiency: The Right Baling Wire for Agricultural Success

Spring into Efficiency: The Right Baling Wire for Agricultural Success

Spring brings a flurry of activity on the farm, from planting to early harvests, making efficient practices crucial. Baling wire, a fundamental tool in agricultural operations, ensures that tasks like hay and straw baling or supporting orchards and vineyards are performed seamlessly. Understanding the specific baling wire needs for these tasks is key to a productive season.

The Essential Role of 14.5 Gauge Bale Wire in Agriculture

For hay and straw baling, the 14.5 gauge baling wire stands out as the industry standard. Its optimal balance of strength and flexibility makes it perfect for securing bales tightly, ensuring they hold their shape and integrity during transport and storage. This wire’s length is 6,500 feet and the 14.5 gauge are specifically designed to maximize efficiency in the baling process, reducing waste and saving time.

Galvanized Wire: The Choice for Orchards and Vineyards

When it comes to supporting the growth of orchards and vineyards, galvanized straight and cut baling wire is the material of choice. Its corrosion-resistant properties make it ideal for outdoor use, where exposure to the elements is a given. Whether it’s training young vines or trees or providing a structured path for growth, galvanized wire ensures durability and reliability season after season.

Galvanized HT Wire: For Enhanced Strength and Durability

In applications where additional strength is required, galvanized high tensile wire (also known as HT wire) offers the perfect solution. Its enhanced durability makes it suitable for trellising in vineyards and orchards, supporting the weight of growing plants without sagging or breaking. This ensures your crops are well-supported for optimal growth and yield.

Selecting the Right Wire for Your Farm

Choosing the right baling wire involves considering the specific needs of your operation. The 14.5 gauge baling wire is ideal for baling operations, while galvanized and HT wires cater to the structural needs of orchards and vineyards. Factors such as the size and weight of bales, the type of crops, and environmental conditions should influence your decision.

Why Midwest Bale Ties?

At Midwest Bale Ties, we understand the critical role that baling wire plays in agricultural efficiency. Our products are crafted from high-quality materials to meet the rigorous demands of farming operations. We offer 14.5 gauge 6,500 foot bale wire tailored for hay and straw baling and a selection of galvanized wires for orchards and vineyards, ensuring you have the right tools for a successful harvest.

As spring ushers in a season of growth and renewal, having the right baling wire on hand is essential for keeping your agricultural operations running smoothly. With Midwest Bale Ties, you can be confident in your choice of baling wire, knowing it’s designed for the specific challenges and opportunities of the farming season.

For more information on our baling wire products or to discuss your specific needs, visit MidwestBaleTies.com or contact our sales team at 765.364.0113. Let’s make this farming season your most efficient yet.

Bale Wire 101: Understanding the Essentials with Midwest Bale Ties

Bale Wire 101: Understanding the Essentials with Midwest Bale Ties

Baling wire serves the crucial role of bundling and securing materials into compact, manageable bales. In this installment of our Bale Wire 101 series, we delve into the nuances of bale ties, their types, materials, industry applications, and selection criteria to ensure you’re equipped with the knowledge to choose the right wire for your needs.

The Three Main Types of Bale Ties

- Single Loop Bale Ties: Designed for manual bale tiers, single loop bale ties are ideal for facilities that handle baling operations by hand. Their ease of use and flexibility make them a preferred choice for smaller-scale or less automated operations.

- Boxed Baling Wire: Engineered for single ram balers, boxed baling wire comes in a form that facilitates automatic feeding and tying, streamlining the baling process in high-volume or automated environments.

- Stem Wire: Also known as carrier baling wire, stand wire, or stump wire, stem wire is used in high-production double-ram balers, or two-ram auto-tie balers.

Materials: Galvanized vs. Black Annealed Wire

Baling wire is crafted from two primary materials, each with unique properties catering to specific needs:

- Galvanized Wire: Known for its corrosion-resistant zinc coating, galvanized wire is the go-to for baling cleaner products where maintaining the integrity of the baled materials is paramount. Its resilience to environmental factors makes it suitable for outdoor storage and handling.

- Black Annealed Wire: Renowned for its flexibility and strength, black annealed wire is treated through a thermal annealing process to enhance its ductility. This makes it an excellent choice for baling materials with memory, such as rubber, allowing for expansion without compromising the bale’s integrity. However, it’s worth noting that black annealed wire may leave a residue on the baled products.

Industries and Applications

Baling wire finds its application across a myriad of industries, each with its specific requirements:

- Recycling and Waste Management: Facilitating the efficient bundling of materials like paper, cardboard, plastics, and metals, baling wire aids in the transport and processing of recyclables. It ensures that recyclable materials are kept compact and manageable, enhancing the efficiency of recycling operations and reducing environmental impact.

- Agriculture: In the agricultural sector, baling wire is crucial for packaging hay, straw, and other fibrous materials, ensuring ease of handling and storage. This not only preserves the quality of agricultural products but also maximizes space efficiency in storage and transport.

- Construction and Demolition: Beyond its conventional uses, baling wire serves as a quick and reliable solution for tying together construction materials such as rebar, contributing to the structural integrity of buildings and infrastructure projects. Additionally, baling wire is extensively utilized in securing and supporting ceiling systems and suspended utilities within buildings.

- Manufacturing: From securing bundled goods for shipment to compacting waste materials for disposal, baling wire is integral to maintaining an organized and efficient manufacturing environment. Beyond its role in logistical support within facilities, it offers a unique advantage by enabling manufacturers to bale packaging overages. Instead of incurring costs to dispose of excess materials, companies can transform this would-be waste into an additional source of revenue by baling and selling it.

Selecting the Right Baling Wire

Choosing the appropriate baling wire involves considering various factors such as:

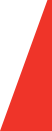

- Gauge: The thickness of the wire should match the weight and density of the material being baled and weight of bale being made

- Length: The length of the wire should be compatible with the size of the bales and the capacity of the baling equipment.

- Material: Consider the end use of the baled materials and any specific requirements, such as residue-free bales or weather resistance.

We are Here to Help!

Selecting the right baling wire is crucial for optimizing your baling operations, ensuring safety, efficiency, and the integrity of your baled materials. Whether you’re baling for recycling, agricultural, construction, or manufacturing purposes, understanding the types of bale ties, their materials, and applications is key to making an informed decision.

If you’re uncertain about the best baling wire for your needs, the experts at Midwest Bale Ties are here to assist. With our extensive knowledge and comprehensive range of baling solutions, we can help you find the perfect wire for your job. Contact us today, and let’s ensure your baling operations are as effective and efficient as possible.

Commercial Businesses and Cardboard Baling: The Holiday Season Surge

Commercial Businesses and Cardboard Baling: The Holiday Season Surge

The holiday season is synonymous with a spike in consumer spending and a corresponding increase in packaging waste, particularly cardboard. For commercial businesses, this seasonal surge presents both a challenge and an opportunity in terms of waste management and sustainability practices. An integral component of this process is the effective baling of cardboard, a task that is streamlined by the use of reliable bale ties. Retail giants, local stores, and distribution centers alike see an exponential rise in packaging, particularly from e-commerce platforms like Amazon, Target, Walmart and the like.

The Holiday Rush and Its Impact on Cardboard Waste

The last quarter of the year, marked by major shopping events like Black Friday, Cyber Monday, and the Christmas season, sees a substantial increase in cardboard usage. Retailers, shipping companies, and e-commerce platforms, including giants like Amazon, face the daunting task of handling an influx of cardboard boxes. Efficiently managing this increase is crucial to prevent operational bottlenecks and promote environmental sustainability.

The Importance of Cardboard Baling

Cardboard baling is the process of compressing cardboard waste into compact, manageable bales, which can then be easily transported for recycling. This process not only helps in reducing the physical space occupied by the waste but also plays a significant role in the recycling chain. Efficient baling is dependent on the quality of bale ties, which must secure the bales effectively to withstand transport and processing stresses.

Bale Ties: The Unsung Heroes in Cardboard Recycling

The effectiveness of cardboard baling is largely determined by the bale ties used. During the holiday season, the increased volume of cardboard waste necessitates the use of sturdy, reliable bale ties. Midwest Bale Ties offers a range of bale ties that are designed for various types and volumes of cardboard bales. From high-tensile strength for heavy-duty baling to more flexible options for smaller operations, the right bale ties can significantly improve the efficiency of a business’s recycling efforts.

The Process of Cardboard Baling

During the holiday season, businesses often adjust their waste management processes to handle the increased volume of cardboard. This includes setting up additional baling schedules, ensuring the availability of adequate baling supplies like wires and ties, and sometimes even upgrading their baling equipment. The compressed cardboard bales are then collected by recycling firms, where they are processed and eventually transformed into new cardboard products, completing the recycling loop.

The Importance of the Right Bale Ties

For these businesses, the choice of bale ties becomes crucial in managing this uptick efficiently. Bale ties are not just about keeping the cardboard compact; they’re about ensuring safety, enhancing recyclability, and improving overall efficiency. But how do you know which bale tie is right for your needs? Midwest Bale Ties offers a comprehensive guide to help you make the best choice for your specific requirements.

The Environmental and Economic Benefits

Efficient cardboard baling during the holiday season not only helps businesses manage waste more effectively but also contributes to environmental conservation. By recycling cardboard, businesses help reduce the demand for virgin paper pulp, thereby conserving natural resources and reducing their carbon footprint. Economically, efficient waste management can lead to cost savings in waste disposal and can enhance a business’s reputation as an environmentally responsible entity.

Embracing Sustainability This Holiday Season

The holiday season’s surge in cardboard waste is a challenge that, when managed effectively, can yield significant environmental and economic benefits. The key lies in the efficient baling of this waste, a process made seamless and effective with the use of quality bale ties from Midwest Bale Ties. As businesses navigate the busiest shopping season of the year, attention to cardboard waste management is crucial for sustainable operations and cost savings.

Looking for reliable bale ties for your holiday season recycling needs? Explore Midwest Bale Ties’ range of products and join the effort to make this holiday season greener and more sustainable. Our team is standing by and ready to assist you at 765-364-0113.

From Metal Scraps to Superior Steel: The American Wire Story

From Metal Scraps to Superior Steel: The American Wire Story

In a world increasingly dominated by disposable products, the recycling and repurposing of materials stand out as a beacon of sustainability and resourcefulness. At the heart of this is the story of American-made steel wire, particularly the kind Midwest Bale Ties is proud to work with.

Collection of Scrap Metal

The journey starts in scrapyards, factories, and homes across the U.S. Old cars, discarded appliances, and construction debris, among others, serve as goldmines for the valuable scrap metal that forms the base of our steel wire.

melting and refinement

This collected scrap metal is then transported to steel mills. Here, it’s melted down in large furnaces. The impurities, often called “slag”, rise to the top and are removed. What remains is molten steel, ready for shaping and refining.

Drawing and Shaping

Once the molten steel is at the desired purity and consistency, it’s drawn into wire forms. It’s passed through a series of dies that progressively decrease in size, allowing for the creation of steel wire of various diameters suitable for different applications.

Crafting Midwest Bale Ties and Wire Products

The wire, once formed, is now ready for transformation into the diverse range of products Midwest Wire offers:

- Baler & Box Wire: Essential for bundling and ensuring materials remain intact.

- Ceiling and Hanging Wire: Crafted for durability and strength, perfect for support systems.

- Straight and Cut Wire: Precisely cut to fit an array of applications.

- Stump and Stem Wire: Specialized wires for unique industrial tasks.

Quality Assurance

Every piece of wire and every product undergoes stringent checks. It’s not just about meeting industrial benchmarks, but upholding the promise of American quality and the unmatched durability of steel.

Discover the Difference of American Craftsmanship! Dive deeper into our range of products and see firsthand the quality and precision of Midwest Bale Ties.

The Role of Midwest Bale Ties’ Galvanized Wire in Powder Coating

The Role of Midwest Bale Ties’ Galvanized Wire in Powder Coating

Galvanized wire is celebrated for its durability, rust resistance, and versatility, offering a host of applications in various industries. At Midwest Bale Ties, we’re proud to provide top-tier galvanized wire that can stand the test of time, proving essential even in niche applications like powder coating. This blog post dives into how our galvanized wire significantly contributes to the powder coating process.

What is Galvanized Wire?

Our galvanized wire is made by dipping steel wire into molten zinc, a process known as hot-dip galvanization. This results in a protective layer of zinc that resists rust and corrosion, making the wire suitable for long-term use in challenging environments.

Midwest Bale Ties’ galvanized wire is renowned for its consistent quality, high strength, and reliable performance, making it an excellent choice for industries that require long-lasting, corrosion-resistant wire.

Application in Powder Coating

Powder coating is a finishing process used primarily for metal objects. It involves applying a dry, free-flowing powder (usually a thermoplastic or a thermoset polymer) to a surface, which is then heated (cured) to form a protective, decorative finish that is tougher and longer-lasting than conventional paint.

Midwest Bale Ties’ galvanized wire plays a critical role in this process. The items to be coated are often hung on wire racks before undergoing the powder coating process. Here, the quality and strength of the wire used are paramount, as it must withstand not only the weight of the items but also the high curing temperatures, which can reach up to 200°C (392°F).

Our galvanized wire, with its robust strength and superior heat resistance, is the perfect candidate for the job. Its high melting point ensures it remains stable and maintains its integrity throughout the heat-intensive curing process. In addition, its corrosion-resistant properties make it suitable for repeated use, even in harsh powder coating environments.

Moreover, the galvanized wire’s clean, smooth surface ensures it does not interfere with the powder coating process by introducing contaminants, ensuring a high-quality, consistent finish.

Take the Next Step

Midwest Bale Ties’ galvanized wire’s strength, durability, and resistance to heat and corrosion make it an invaluable asset in the powder coating industry. The wire’s superior qualities not only aid in the efficient application of powder coating but also contribute to a superior final finish, making it a go-to choice for businesses in this sector.

If you’re in the powder coating business and need high-quality galvanized wire that delivers excellent results, look no further than Midwest Bale Ties. For inquiries or more information, call our sales team today at 765-364-0113.

How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

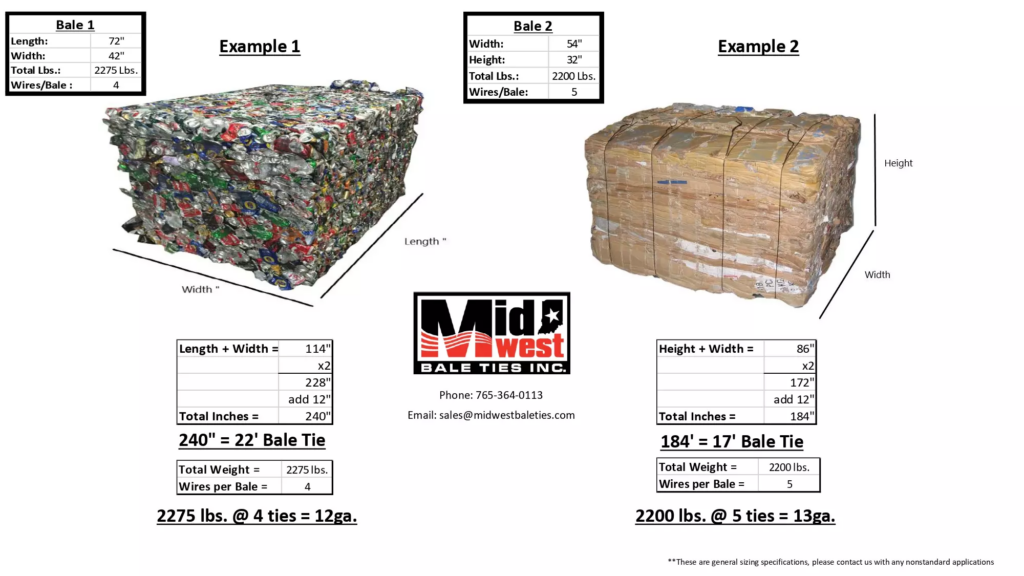

Measure your bale

Weigh your bale

Understand what is being baled

Count your wires

Looking For Bale Ties in the Midwest?

Galvanized vs. Black Annealed: What’s the Difference?

Galvanized vs. Black Annealed: What’s the Difference?

Galvanized Wire

How do you Make Galvanized Wire?

Black Annealed Wire

What is Black Annealing?

Painted or Coated Wire

What is Coated Wire?

What is Baling Wire Made Of?

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

What are we baling?

Where are our bales being stored and for how long?

How much do your bales weigh?

What are the dimensions of your bales?

How to Save Money on Bale Ties: Sizing, Quantity, and Freight

How to Save Money on Bale Ties: Sizing, Quantity, and Freight