How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

Bale ties allow us to condense, palletize and easily move a wide variety of recyclable products and waste materials including plastics, paper, aluminum, and cardboard. Compacting using either a horizontal or vertical baler is always followed by the use of some type of securement often times this comes in the form of a bale tie. Bale ties are most commonly used in vertical balers and sometimes used in horizontal balers. Properly sizing your baler for the correct bale tie will likely save you time and or money down the line. Here are some tips to help you navigate your way through sizing:

Measure your bale

The first and most important thing to do when trying to get to the correct size of bale tie is measuring your bale. Grab a tape measure and get the full dimensions of an already completed bale. If you are working with a vertical baler you will need measurements on height and width and if you are working with a horizontal baler you will need measurements for width and length. These measurements will directly impact the length of your bale tie.

Weigh your bale

You have your measurements, now its time to get your bale to a scale and see how much your made bale weighs. This weight doesn’t need to be exact but you should be able to get somewhere within 10 lbs. of an accurate weight. You might also consider weighing multiple bales and averaging the group. It’s common for bales to vary in weight depending on who makes the bale and who is feeding the baler. The weight of the bale will help diagnose the gauge or thickness of wire that will best fit your needs. The most common gauges requested are 12 gauge and 13 gauge however 11 gauge and 14 gauge are also available.

Understand what is being baled

Now that you have your measurements and your weight it’s time to understand and think critically about the composition of the straight you are processing. A material like paper doesn’t really have much expansion once the baler releases the bale, however a straight like plastic will expand. This is important to understand because this may affect the type of finish (black annealed or galvanized) bale tie will best fit your application.

Count your wires

This one is simple, how many wires do you use to make a bale with your particular type of baler? This number, like the weight of your bale, also helps us calculate what gauge bale tie will be most effective for your system.

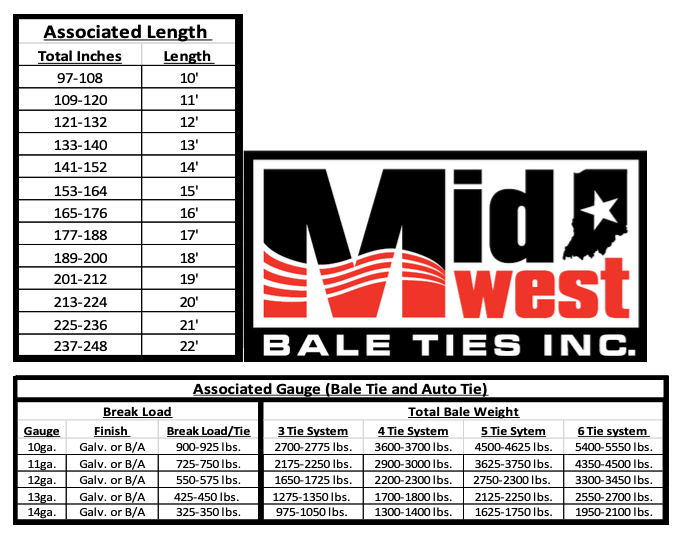

So, we have a bale measured and weighed, we know we are baling paper so not too much expansion after release and we know we are using 5 wires per bale in the vertical baler we are using, what now? Now we just use the formula of (height”+width”)x2+12”. So, for example, we will use the height of 48” and a width of 38” for a total of 86”. Now we have 86” times 2 gives us 172” plus 12” comes to 184”. Using the chart below we know we need a 17’ bale tie.

Now we have our length its time to calculate our gauge and finish. Our bale weighs 2200 lbs. and we know we are using 5 wires per bale. So using the other chart below we can see that 13ga wire has a break load strength of 425-450 lbs. we take that 425 and multiply by 5 and we get 2,125-2,250 lbs. of total break strength. We also know we are baling paper so not too much expansion after release so we can go with a standard galvanized finish.

Looking For Bale Ties in the Midwest?

Feel free to use the materials and examples below to do your own sizing assessment, shaving off a couple of feet or going to a lighter gauge could save you up to 10% on cost and the correct length could help cut time off on tying off the bale. Also, keep in mind we do samples bundles of 20-25 wires if you would like to try a different length or gauge bale tie than the one you are currently using. If you have any questions or would like to request a sample bundle please don’t hesitate to email sales@midwestbaleties.com or call 765-364-0113.

Asking and answering the questions above and communicating that information to your supplier should allow them to accurately and efficiently give you the best and most cost-effective length and gauge product. We offer free samples on bale ties and baler wire to customers who are looking to get hands-on experience with a different gauge or length of tie and encourage anyone to reach out with questions or requests. In addition, we offer a sizing chart to better understand if you are getting the correct material for your current system.